Sampling Valves

Sampling Valves are used for taking material samples from reactor vessels, pump outlets, pipelines etc.

At Amarama Engineers, we design & manufacture various models of Sampling Valves for varied applications like Reactor Vessels Top Sampling, Reactor Vessels Bottom Sampling, Pump Outlet / Pipeline inline Sampling Systems with Contactless Secure Sampling Cabinet where the operator doesn’t come in contact with the service or the media. We also provide automated solutions and systems with PLC control panels (Ex d & Ex i).

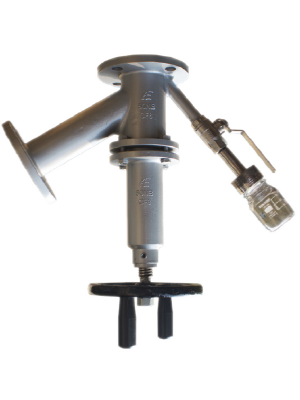

For Reactor Bottom Sampling and Pipeline Sampling, our glandless sampling valves open downwards (in the valve), consists of hard chrome plated piston & PTFE Seats & Seals which ensures 100% shut off & zero contamination of the material.

At Amarama, we have indigenously developed a sampling cum flushing valve with zero hold up and zero cavity, where there is a separate outlet for sampling and a separate outlet for flushing. To install the valve you will not need any modification to your vessel or reactor. This valve is manufactured as per your bottom pad flange dimensions only. We also automate this valve

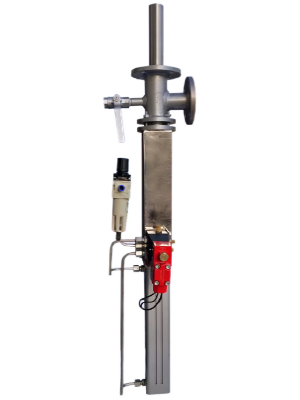

We manufacture each valve to the precise dimensions of the vessel provided by the client to ensure ZERO hold up, thus avoiding any contamination taking place in the next batch of material being processed in the vessel. We can also provide a limit switch, cylindrical actuator, FLP solenoid valve and other accessories as per your requirements.

For Reactor Top Sampling, Inline and Pump outlet Sampling applications, our Inline Sampling System with Contactless Secure Sampling Cabinet is a one stop solution for safe, secure and reliable sampling from your running system without interfering with your continuous process. This system is totally customisable to your process requirements and can be provided with inert atmosphere sampling, sampling under full vacuum conditions with PLC control Panels (Ex d & Ex i approved) where feedback can be taken from ATEX approved solenoid valves, proximity sensors, temperature sensors, pressure sensors.

SAMPLING CUM FLUSHING VALVE

PIPELINE SAMPLING SYSTEM (GLANDLESS Y & PISTON TYPE SAMPLING VALVE)

SAMPLING VALVE WITH CYLINDRICAL ACTUATOR

REACTOR TOP SAMPLING WITH CONTACTLESS SECURE SAMPLING CABINET

- Zero Hold Up

- 100% Shut Off

- No outlet reduction

- Tight shut off

- Jacketed

- Sampling cum Flushing with Zero Hold Up.

- Opening downwards

- Glandless

- Extended outlet

- Cylindrically Actuated

- Bottom Sampling

- Top Sampling

- Pump Sampling

- 100% Customization

| Type | Flanged or Screwed |

| MOC | CS, SS304, SS304L, SS316, SS316L, Hastelloy ‘C’ 276, Hastelloy ‘C’ 22, PTFE / PFA lined and other exotic alloys available on request. |

| Size Range | 15NB to 300NB (Higher sizes available on request) |

| Sealing | PTFE, Graphoil |

| Pressure Ratings | 150#, 300#, 600#, 900# |

| Seat MOC | PTFE (Leakage Class VI) |

| Flange Connections | BS, ANSI & DIN Standards |

| Actuated | Cylindrical |

| Manual Override | Bottom Mounted or Side Mounted |

Get in touch to request a quote and more details