Breather Valves & Emergency Relief Vents

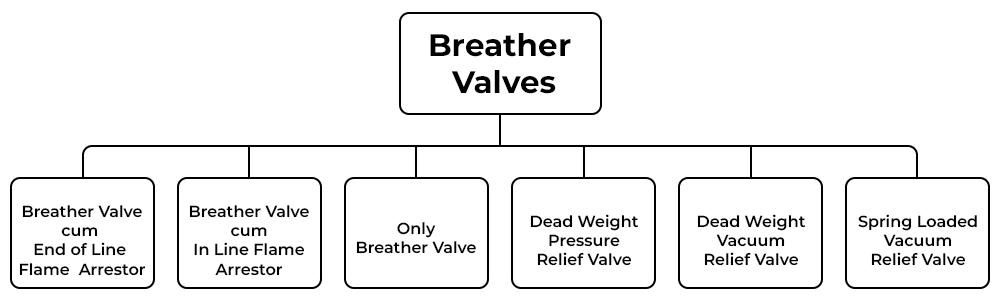

Breather Valves are installed on the vent nozzle of atmospheric storage tanks for providing adequate pressure and vacuum relief in Thermal Inbreathing,Thermal Outbreathing, Pump In and Pump Out Scenarios, which helps in preventing bulging and buckling of atmosheric storage tanks. Breather Valves also help in considerably reducing vapour & nitrogen losses therefore reducing harmful emmissions to the atmosphere.

At Amarama Engineers we have developed a unique single piece design casted Breather Valve with an intergrated Flame Arrestor. The single piece design helps in easy maintenance, longer life of the pallets due to less chattering and the flame arrestor element.

Our design is adaptable for both underground and above ground storage tanks. For underground storage tanks we offer Breather Valve cum In-Line type Flame Arrestors with which you can continue the vent line upwards and end it with a U bend, this helps in preventing the vapour to be released into the atmosphere at human level, for above ground tanks we offer Breather Valve cum End of Line Flame Arrestor. We can also provide separate Nitrogen inlet thru the breather valve into the storage tank in this design for applications where the service / media is sensitive to atmospheric air contact.

We have also designed & developed long term solutions for corrosive process applications like our PTFE lined Breather Valves, Dead Weight Pressure Relief Valves & Vacuum Relief Valves with PTFE pressure & vacuum pallets. Our design ensures that only PTFE comes in contact with the material of acidic nature, which helps in applications where various metal alloy’s corrode because of the corrosive nature of the material.

Over the years we have adapted our designs for various pressure, vacuum, corrosive & temperature applications. Our One Piece Designed Dead Weight pallets are made with utmost precision which ensures tight shut off and reduces the chattering of the pallet considerably. The dead weight type pallets can be replaced at a later stage if your process requirements have changed.

Our Emergency Relief Vents are designed for storage tanks where emergency pressure relief is required in case of external fire in the immediate surrounding area. Our hinged pallet design ensures you get easy access to the vessel. Our soft seating ensures tight sealing & sparking doesn’t take place. We also have a spring loaded design for higher set pressures. Our size ranges from 4” (100NB) to 32” (800NB).

We provide end to end tank blanketing solutions to our clients with our range of Breather Valves, Flame Arrestors, Emergency Relief Vents, Back Pressure Relief Valves, Pressure Regulating Valves and Stations. We also assist with the required sizing and selection of Breather Valves & Emergency Relief Vents in accordance with API 2000.

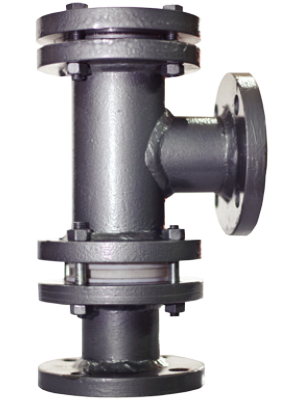

BREATHER VALVE cum END-LINE FLAME ARRESTOR

BREATHER VALVE cum IN-LINE FLAME ARRESTOR with SEPARATE NITROGEN INLET

BREATHER VALVE cum IN-LINE FLAME ARRESTOR

PTFE Lined BREATHER VALVE

EMERGENCY RELIEF VENT

PTFE Lined DEAD WEIGHT PRESSURE RELIEF VALVE

- Tight shut off

- Soft seating

- Easy Maintenance

- Intergrated Flame Arrestor Design

- Longer life

- Dead Weight type

- Long term solutions for Corrosive applications

- Minimal Dead Weight Pallet Chattering

| MOC | CS, SS304, SS304L, SS316, SS316L, Hastelloy ‘C’, PTFE Lined , PFA Lined, PP, PVC and other alloys & lining available on request. |

| Size - Metal alloys for Breather Valves: | 1” (25NB) to 12” (300NB) |

| Size - Metal-PTFE Lined for Breather Valves: | 1.5” (40NB) to 6” (150NB) |

| Size for Emergency Relief Vents: | 4” (100NB) to 32” (800NB) |

| Pressure Ratings: | 150#, higher pressure ratings available on request. |

| Seat MOC | PTFE, Neoprene, Silicon, Nitrile , EPDM , FFKM |

| Pressure & Vacuum Pallettes: | SS316, Hastelloy ‘C’, PTFE |

| Flange Connections: | BS, ANSI & DIN Standards. |

| Manufacturing Standards: | API 2000 |

Get in touch to request a quote and more details