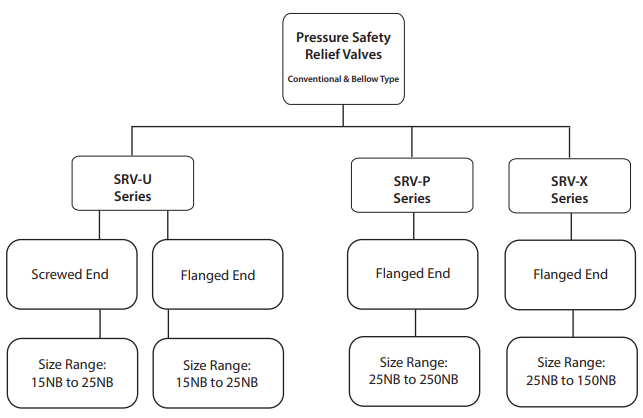

Pressure Safety Relief Valves

Amarama Engineers designs & manufactures spring loaded Conventional & Bellow Type Pressure Safety Relief Valves which are installed to release the excess pressure developed in a system like reactor vessels, pipelines due to a chemical reaction, pump outlets, thermal expansion etc. Our Pressure Safety Relief Valves can be used for thermal relief applications also.

Our full nozzle inlet design gives quick release of pressure and faster shut off on the return. Through our years we have categorised our range of springs for different pressure and sizes of valves.

The flexibility in our design helps us cater to different applications like corrosive, utility, high pressure, temperature, hydrogenation, reactor jacket, bitumen blending & many more applications.

We have developed Bellow type Safety Relief Valves for applications where there is back pressure, high temperatures, corrosive applications, etc. Our Bellow design isolates the working parts i.e. Spring, Spring Washer, Spindle, Pressure Set Bolt, etc. from the service gas / liquid, this ensures the valve opens at the given set pressure and is not corroded or damaged because of the service gas / liquid. Our Bellow type valves are available across our SRV-U Series, SRV-P Series & SRV-X Series.

Our SRV-X Series Bellow type Pressure Safety Relief Valves are designed for applications where PTFE, PFA & GFT (minimum 3mm thick) will only come in contact with the service / media at the inlet and outlet side of the valve. The advantage of this design is that you can connect the outlet to a scrubber, dump tank which is also contact corrosive vapours therefore ensuring zero corrosion throughout the valve.

We also assist our customers with the sizing and selection of Pressure Safety Relief Valves according to API 520 & API 526. At Amarama, we test 100% of our Pressure Safety Relief Valves in accordance to API 527.

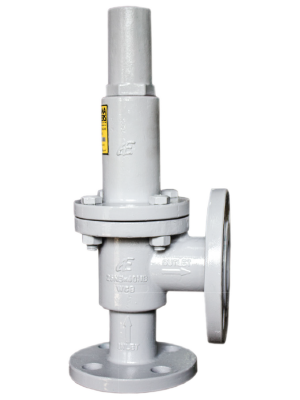

SRV P SERIES PRESSURE SAFETY RELIEF VALVE

SRV P SERIES PTFE LINED PRESSURE SAFETY RELIEF VALVE

SRV P SERIES JACKETED PRESSURE SAFETY RELIEF VALVE

SRV U SERIES FLANGED END SRV / TRV

SRV U SERIES Screwed End SRV / TRV

- Full Nozzle

- Soft seating

- Easy Maintenance

- Jacketed

- Extensive Spring Range

- Class VI Shut Off with Metal to Metal Seat as per API 527

- Bellow type for Back Pressure, Corrosive, and High Temperature Applications,etc.

- * SRV-X Series for Extreme Corrosion

| MOC | CS with SS304/SS316 Nozzle, SS304, SS304L, SS316, SS316L, Hastelloy ‘C’, PTFE Lined and other alloys available on request. |

| Flanged End | 15NB to 250NB |

| Screwed End | 15NB to 25NB |

| Pressure Ratings | 150#, 300#, 600#, 900# |

| Seat MOC | PTFE, GFT, SS316L, Hastelloy ‘C’ 276, Hastelloy ‘C’ 22 |

| Bellow MOC | PTFE, SS316, Hastelloy ‘C’ |

| Cap type | Screwed, Bolted |

| Flange Connections | BS, ANSI & DIN Standards |

| Manufacturing Standards | API 520, API 526, API 527 |

Get in touch to request a quote and more details